Z12ZT

Key Features

● ZT series spring-pressurized electromagnetic brake is a dry electromagnetic brake with friction structure released after power-off braking and power-on. This series of brakes have excellent and lasting braking torque and are widely used in forklifts, lifting equipment, logistics and storage equipment, braking motors, reduction motors, construction, packaging equipment, electric moppers, electric rolling gates and various automation equipment.

● ZT series electromagnetic brakes are divided into two categories: one is-T type (that is, the braking torque of the brake can be adjusted by adjusting the ring and the force transmission column); the other is ordinary type brake (that is, the braking torque of the brake cannot be adjusted).

● ZT series electromagnetic brakes achieve good F-class insulation pressure resistance, low working noise, wide applicable voltage range (42-460V), and large braking torque range: 3-1350N.m.

● ZT series electromagnetic brake adopts imported brake pads, which has good friction coefficient, excellent wear resistance and moisture resistance, and meets ROHS and REACH requirements. The products have passed CE certification and brake type test certification of China Bridge and Portal Hoisting Machinery Product Quality Supervision and Inspection Center.

● ZT series electromagnetic brake can be equipped with manual release handle and protective cover according to the use requirements, which is convenient to install and simple to maintain.

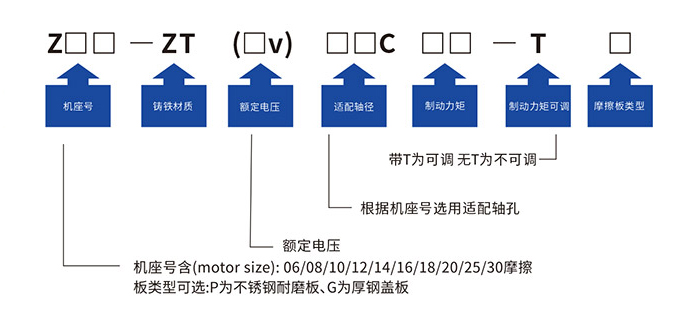

Product code and model description

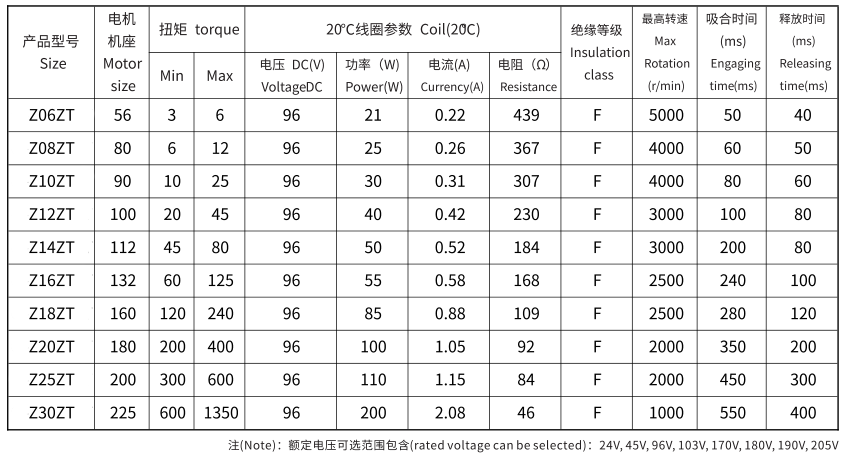

Performance Parameters

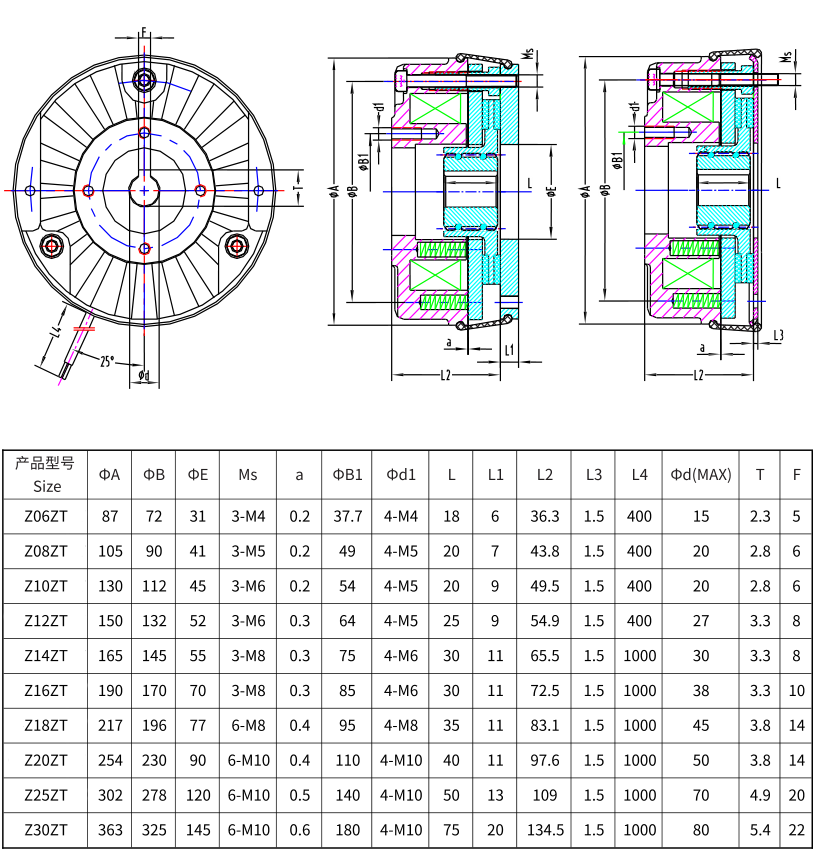

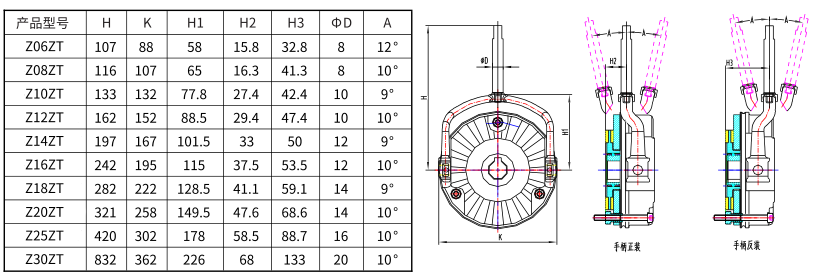

ZT series non-adjustable torque brake size and diagram:

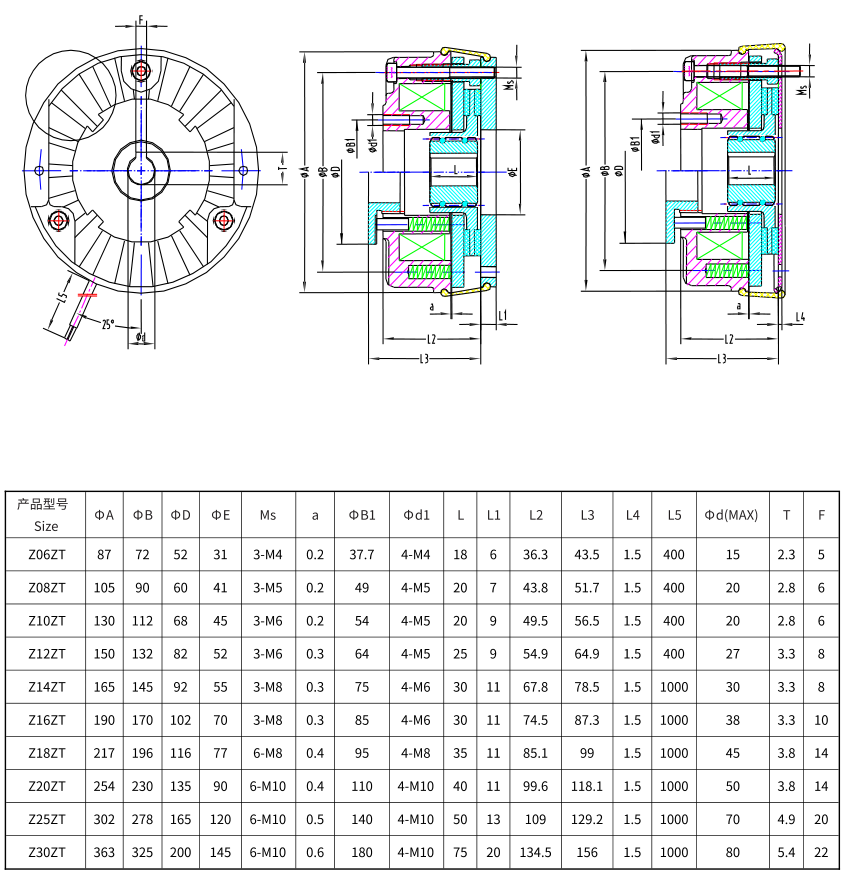

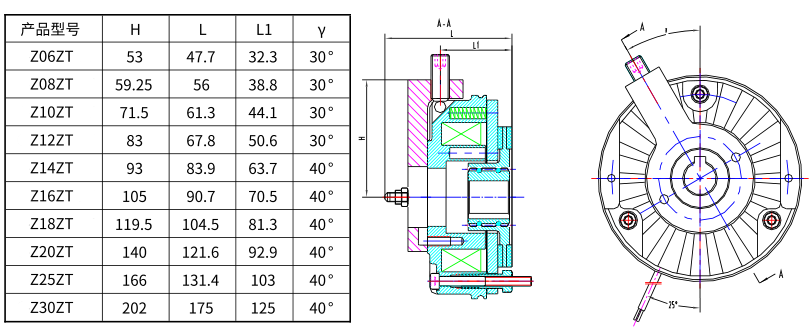

ZT series T type adjustable torsion brake size and diagram:

Release Handle Installation Dimensions

Self-locking screw release mounting dimension

Brake Installation Diagram

Installation Precautions

1. Before installation, check and ensure that the installation plane is flat, flatness ≤ 0.05, roughness ≤ Ra3.2, and perpendicularity between the shaft and the installation end face ≤ 0.05. If the accuracy of the installation surface is poor, noise will occur when the brake is running.

2. During the installation process, avoid knocking, falling or excessive force that may cause the brake to deform and affect its use.

3. During installation and use, liquid substances such as oil stains and water should be avoided on the friction surface, which will cause the brake torque to decline and fail. In order to prevent oil stains, water and dust from entering, a protective cover can be used for protection.

4. The voltage fluctuation will affect the normal use of the brake, and the input voltage of the brake should be controlled within ± 10% of the rated voltage.

5. During installation, the mounting screws must be coated with thread fastening glue to prevent them from loosening. Note that the glue cannot be attached to the rotor, shaft sleeve and suction surface, which will cause the brake to fail to open normally.

6. Special attention must be paid to check whether the brake has been opened when the motor is rotating. Forced operation with brake will cause damage to the brake.